News & Events

Key Points for the Installation of the Stair Nose

A flush stair nose or a edge stair nose, is a length of plastic or metal that protects the edges of stairs that are not already protected by a built-in square or rounded edge. Most stair noses have an L-shaped profile so that they wrap around the front edge of the stair tread and down over the riser, the vertical board just below the tread.

Nosing provides a finished look and help protect the edges of the steps from damage. They make stairs safer by providing a non-slip surface and decorative effect also can be obtained.

There are some things You Should Know for the installation of PVC or other kinds of Stair Nosing.

Stair noses are typically 94 inches long and can be cut to fit the width of narrower stairs, using tin snips or aviation snips (for vinyl nosing), hacksaw (for aluminum nosing). Some of the nosing come with shims and tracks for fixing the strips.

What You'll Need

Equipment / Tools

· Tape measure

· Pencil

· Saw

· Rubber Hammer

· Glues or Screws matched

Materials

· Flush stair nose or a edge stair nosing

· Shim(if needed)

· Track(if needed)

· Nails

Instructions

Make sure the step is flat first, using a tape measure, measure the length of each stair. If the stairs are open on one or both sides, you can mark the nosing, then cut it to length, as needed, using a saw. With aluminum nosing, be careful not to leave metal burrs along the cut edge (aluminum is prone to this). If you see burrs, use a metal file to remove them and smooth the edge.

Take the edge stair nose as an example:

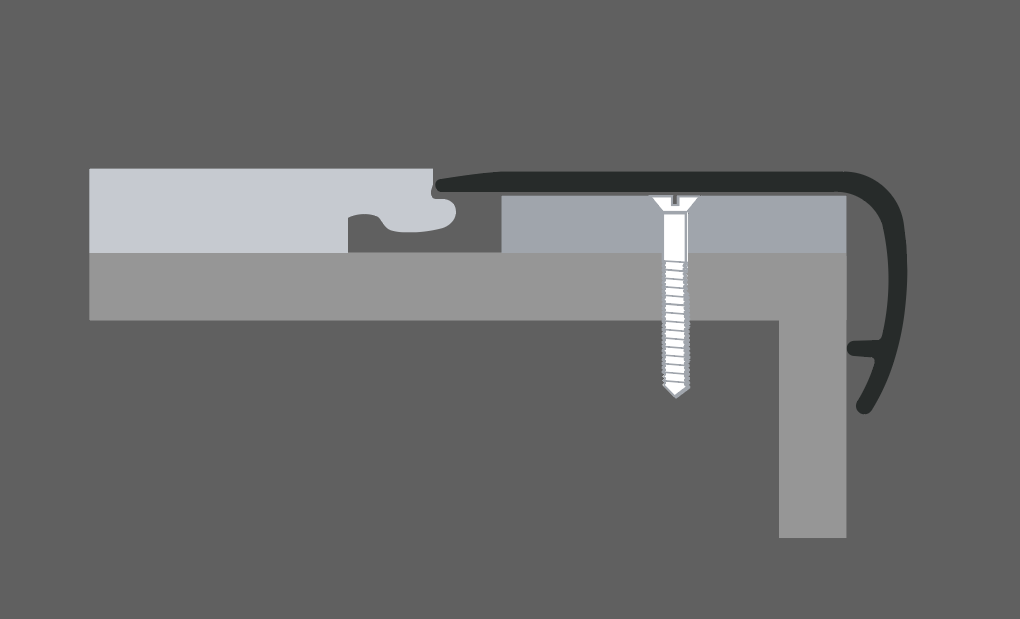

The surface of the nosing is very thin so that it can be covered on the floor directly without creating a large height difference. Apply glue in the place of the outside of floor that will be covered, make the supporting point of vertical side cling to facade, Press for a while to keep it fixed.

The side of the nosing can also be connected to the click of the floor with the support of the shim, so that the problem of the height difference can be removed or reduced.

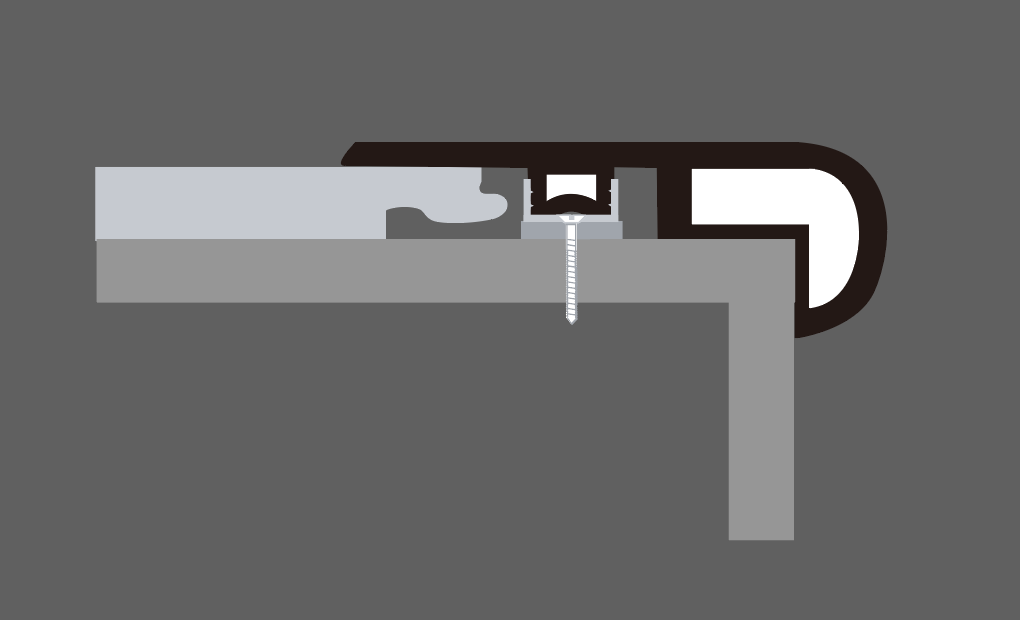

Except for the glue, the stair nose with the catching groove can also be fixed to the ground by the track. The buckles will be perforated at regular intervals in the tracks and screws can be used to fix the tracks on the ground through these holes.

You need to measure and calculate the place of the tracks according to the distance to the right angle of the stair nose, and usually the floor will also keep a little distance from the track at the other side, in case the expansion of the floor. Then press the stair strip down against the track When you're sure it's stuck to the bottom or locked tightly.

Sometimes shims are also used to adjust the height difference between the floor and the stair nose in case it is suspended between them, so that the nosing of standard size can be matched with the floor of different thickness.

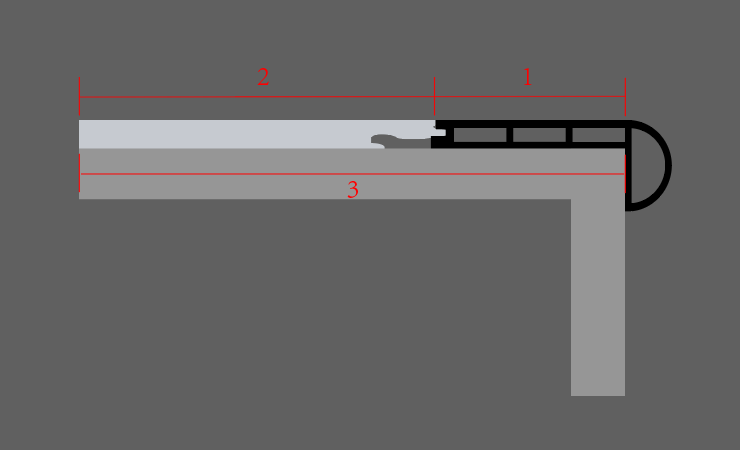

If it is flush stair nose has the groove that can be connected with the click of floor, a high requirement of the matching degree will be needed for the stair nosing, the height need to be totally the same as the floor, and the tongue and groove need to be matched, then you should cut the width of the floor by calculating the length of 3 minus the length of 1, and stick the floor first and install the flush stair nose in the end.

.png?v=20250420)

Richard Liu

Richard Liu +86.519.8585.1798 Fax:+86.519.8585.6878

+86.519.8585.1798 Fax:+86.519.8585.6878 info@xinflooring.com ( 7*24 hours online)

info@xinflooring.com ( 7*24 hours online) Science & Technology, Industrial Park, Hutang Town, Wujin District, Changzhou City, Jiangsu Province, 213162, China.

Science & Technology, Industrial Park, Hutang Town, Wujin District, Changzhou City, Jiangsu Province, 213162, China.