News & Events

Luxury Vinyl Floor Installation Guide (A)

The Subfloor

The subfloor must be permanently dry, even, sound and crack-free and then you many proceed. Thehardness of the uppermost layer of the floor can be accessed with a hard, sharp object such as a large nail or chisel. Over a surface area of approx one-meter scratch horizontal and vertical lines approximately 1 cm apart. If the upper layer within the drawn 1cm 2 chequered area does not fall apart, you can assume that the surface is hard enough. Industrial floors are suitable for adhesive application, after special pretreatment (e.g.pre=impregnating or leaving).Follow the advice on this matter from the supplier of your adhesive and leveling facility supplier.

The Moisture Content of the Floor

All floors other than liquid asphalt have maximum permissible moisture content expressed as apercentage by weight(the so-called domestic moisture content).

After installation, all sub-floors require a certain drying time before floor covering can be laid. The drying time depends on the thickness of the construction, atmospheric condition, heating and lighting system, etc. If the moisture content of the underlay structural floor is not within the permissible average domestic moisture content, then the applied, apparently dry top floor is not suitable for bonding hard floor covering. Do pay attention to this point!

Before processing, always measure the moisture content of the floor and ensure that the percentages are appropriate for the type of under floor involved. If in doubt, always consult an expert.

A reliable device for determining the moisture content is a CM-unit. The readings must be confirmed to the client in writing.

N.B. In heated floors, do not use any method for measuring the moisture content of the floor that requires holes to be made (e.g.the CM-unit).Holes could damage the heating system. Where underfloor heating is installed there are usually starting instructions or a so-called heating up protocol. By adhering to this, measurement of the moisture content becomes superfluous.

The permissible moisture content should be as follows:

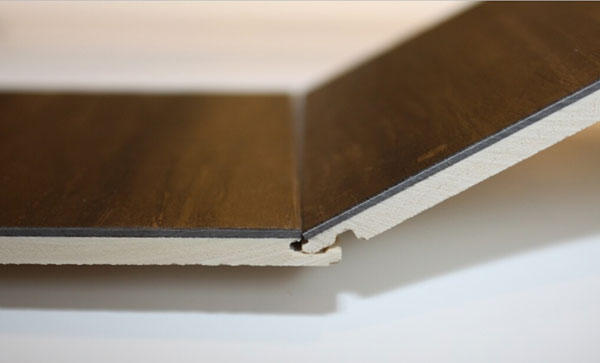

Pre-treatment of the finishing luxury Vinyl floor

In principle, all types of finishing floor must be PRESMOOTHED AND LEVELLED. The slightestunevenness in the under-floor will show up if leveling is omitted. Consult you adhesive and leveling facility supplier if desired. Impregnating and leveling facilities must be used in line with the manufacturer's instructions. They must be applied such that they bond to one another and

permanently to the substrate, do not tear and are absolutely firm. The minimum leveling thickness for a rolling load is 2mm. sealed, non-absorbent substrates must be leveled using sufficiently thick dispersion adhesives, the minimum thickness being 2mm. after wiping off, cut off flow margins along the walls and intersections. The same also applies to any insulating material and protective film still projecting.

Click here to see Luxury Vinyl Floor Installation Guide (B)

See the steps of click vinyl floor installation (100% original photos)

.png?v=20250420)

Richard Liu

Richard Liu +86.519.8585.1798 Fax:+86.519.8585.6878

+86.519.8585.1798 Fax:+86.519.8585.6878 info@xinflooring.com ( 7*24 hours online)

info@xinflooring.com ( 7*24 hours online) Science & Technology, Industrial Park, Hutang Town, Wujin District, Changzhou City, Jiangsu Province, 213162, China.

Science & Technology, Industrial Park, Hutang Town, Wujin District, Changzhou City, Jiangsu Province, 213162, China.