News & Events

SPC Floor Installation Instruction

Installation Instructions

Waterproof Luxury Vinyl Plank SPC Flooring

For Assistance, call: +86 519 85851798

Product Description

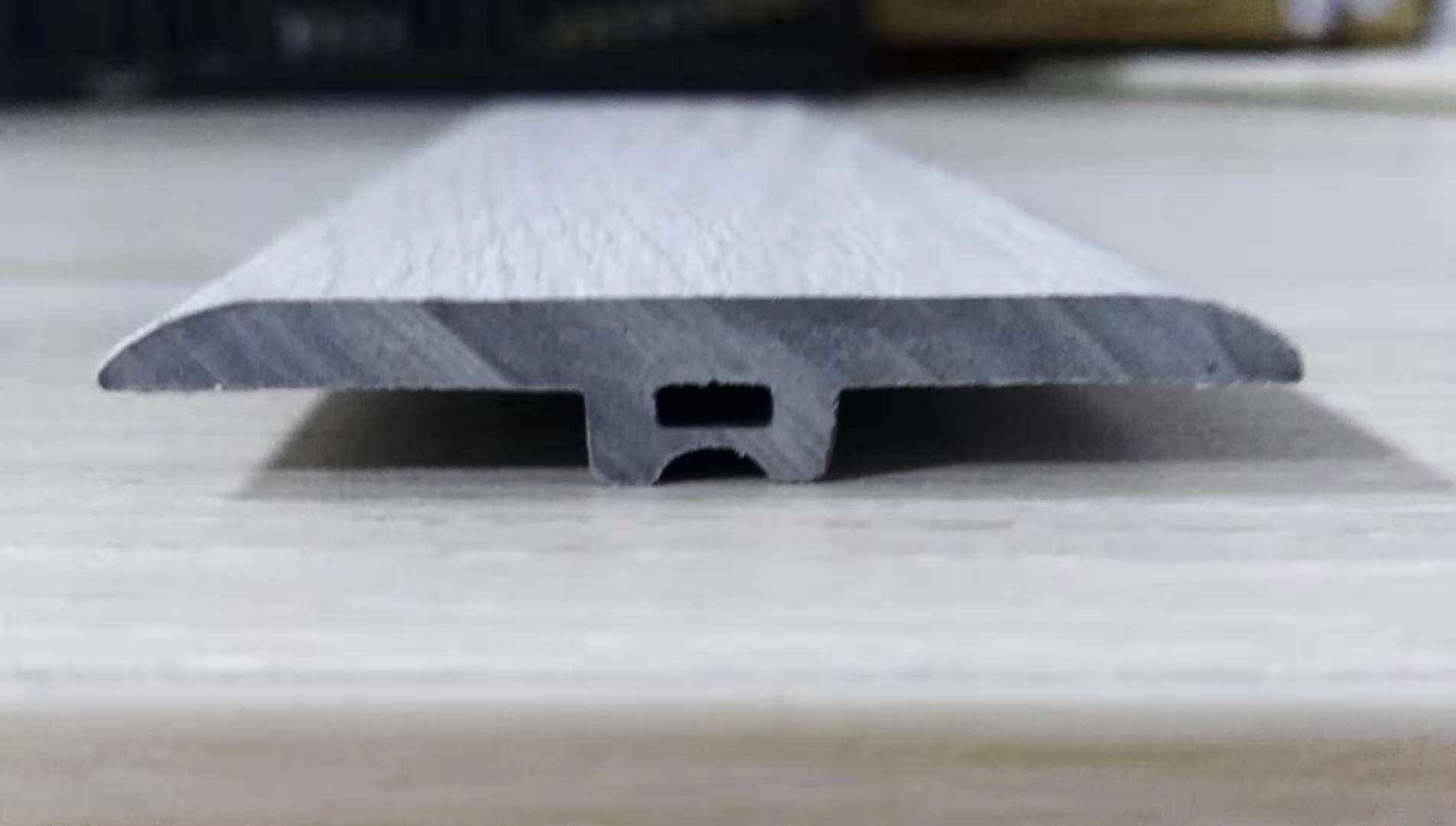

Thickness: 4mm & 4.2mm & 5mm

Size(Width*Length): 6”*48”(152.4*1219.2mm)/7”*48” (177.8*1219.2mm)

Rigid Core Vinyl Planks

Grade Levels

Above Grade/on Grade/Below Grade

Installation Method

Unilin Click/Valinge Click lock system

Pre-Installation

OWNER/INSTALLER RESPONSIBILITY

The owner is advised to be at home during the installation for consultation/direction.The owner and installer should discuss installation and layout to maximize satisfaction.If this is not possible,consultation should be done prior to installation.The owner/installer assumes all responsibility for product quality of competed installation.

PERFORM PREINSTALL INSPECTION.FOR CLAIMS PURPOSES,OPEN UP A COUPLE BOXES FOR PRODUCT INSPECTION. DO NOT OPEN ALL THE BOXES. OPENING ALL THE BOXES CONSTITUTES YOUR ACCEPTANCE OF THE PRODUCT. INSPECT ALL THE PLANKS IN THESE 4 BOXES CAREFULLY. EXAMINE FLOORING FOR COLOR FINISH AND QUALITY.

IF YOU DISCOVER THAT PRODUCTS ARE DEFECTIVE, OR IF MATERIAL IS QUESTIONABLE,YOU SHOULD CONTACT THE RETAILER. IF YOU ARE SATISFIED,PROCEED WITH INSTALLATION.

Prior to installation,rack up planks form several boxes to ensure uniform distribution of colors,shades and characters in the installed flooring.Planks having similar widths should be place together in the same row to minimize gaps between boards .

The installation of spectrum does not require acclimation. However we recommend installation in rooms with temperature between (10℃&38℃).

Purchase flooring to be installed in one large area at the same time.Product purchased at a later time than the first purchase may vary beyond your expectations.

Accessories,trims and moldings are manufactured to coordinate with the varied appearances of the floor .

Any exact matches are coincidental.Non-matching accessories are not defective products.

This product is manufactured according to strict quality standards.In the event that defects are discovered in the field,the industry standards permit a defect tolerance not to exceed 5%.Order an additional 10% extra for cutting wastage and grading allowances(more for diagonal installations).

During installation,inspect the planks continuously.Defects that can be seen form a standing position should be cut off or held out.Installing defective planks implies acceptance.

Clicking noises are the result of interactions among flooring,joists and sub floors when they move.Sometimes,it is impossible to eliminate them completely and minor clicking noises are to be accepted as normal flooring phenomenon.

To assure the warranty is not inadvertently voided,before proceeding with any activity that is not covered in the manual,please contact our Customer Support Team at 86-519 85851798.

CONCRETE SUBFLOOR REQUIREMENTS

concrete sub floors must:Have minimum rated strength of 3000psi.

Be level to within 1/4 in.in a 10 ft.span;no bumps or low spots.high spots can be removed by grinding;depressions can be filled with patching compound formulated formulated for use in floor installation.Sub floors should not slope more than 1 in.per 6 ft.

Be clean no construction debris soil mud and any other object on or adhering to the floor if necessary scrape and sweep away before the installation no protrusion of nails debris metals should remain.

New concrete slab must cure for at least 90 days It must have a minimum 10 mil polyethylene sheet between the ground and the concrete.

Be free from moisture related conditions which can damage the installed flooring.

CONCRETE MOISTURE

Test all concrete sub floors for moisture content and document the results. Visual checks are not reliable perform tests at location around exterior doorways near walls containing plumbing near foundation walls and in the center of the room.

Minimum sample size is 3 samples per 1000 sq. ft of area and one test for every addition 1000 sq.ft. thereafter.

Moisture content should meet one of the following criteria.

4% max when tested using Tramex Concrete Moisture Encounter

Less then 8 pounds per 1000 sq ft per 24 hours when using Calcium Chloride test (ASTM F1869).

85% max when using Relative Humidity Testing (ASTM F2170).

NOTE: Concrete moisture content may be acceptable the time of the test. These tests do not guarantee a perpetual “dry” concrete slab. The concrete slab moisture content can vary at other times of the year. we are not responsible for moisture-related damage to installed flooring.

WOOD SUBFLOOR REQUIREMENTS

The sub floor must be clean no presence of construction debris soil mud and any other objects on or adhering to the floor no protrusions of nails debris or metals should remain. If necessary scrape and sweep the sub floor before the installation.

The sub floor must be structurally sound and stable no movements or squeaks no

loose panels or loose nails no sings of plyde-lamination or other damage Repair all shortcomings before installation.

The sub floor must be flat no visible bumps or low spots the sub floor should be flat to within 1/4 inches.in 10 ft span. Test for moisture using a reliable moisture meter Perform tests at locations around exterior doorways near foundation walls near walls containing plumbing lines and in the center of the room Measure 20 locations per 1000 sq ft Moisture content of the sub floor should be Less than 13%. Moisture content difference between the sub floor and flooring should be 2% or Less.

PLYWOOD OR ORIENTED STRAND BOARE (OSB) SPECIFICATIONS

On truss/joist spacing of 16 in (406mm) O/C or Less the industry standard for single panel sub flooring is a minimum 5/8 in(19/32 in,15.1 mm)CD Exposure 1 plywood sub floor panels(CD Exposure1) or 23/32 in OSB Exposure 1subfloor panels 4 ft*8 ft sheets Expansion gap between panels should be 1/8 in (3mm). If panels are not tongued and grooved and there is not sufficient spacing or is inadequate cut in the required spacing with a circular saw Do not cut in expansion space on tongue and groove panels.

PARTICULE BOARD OR FIBER BOARD

Only for floating installation.

EXISTING FLOORS

Installation over exiting floor requires the installer to consider potential issues related to moisture damage adhesive failure and fastener failure Contact the adhesive and fastener manufacturers respectively for their specific Installations recommendations and requirements.

Acceptable floor coverings includes Solid hardwood linoleum (1 layer only),terrazzo ceramic and stone tile.Tiled floors with grout lines larger than 1/4 in will require a cementitious leveling compound to fill any grout lines,voids,or cracks.

Unacceptable floor coverings include Carpet (any type),foam underlayment, cushioned-back vinyl,rubber,cork,laminates free-floating floors and wooden floors over concrete.

JOB SITE CONDITION

Prior to installation, the installer must ensure that at the time of installation,the job site conditions including sub floor/substrate, ambient temperature and relative humidity,and all impacting variables will not negatively affect the floor. The manufacturer will decline responsibility for damages associated with improper installation or poor site conditions.

STORAGE AND CONDITIONS

The installation does not require acclimation. However we recommend installation in rooms with temperature between 50°F & 100°F(10°C & 38°C). Product should be stored horizontally in a dry area away from direct sunlight.

Do not leave next to heat or cooling ducts. Ensure that all trades have been completed to eliminate dry wall dust, paints, etc.

Do not store flooring in uncontrolled environmental conditions. For example,garages and exterior patios are not acceptable areas to store flooring. Flooring stored on a concrete slab should be elevated at least 4 in. to allow air circulation under cartons.

EXISTING HOME

An existing home should have a consistent room temperature between 50°F & 100°F(10°C & 38°C) and relative humidity(RH) of 35%-85%. Continual deviation from these conditions will affect the dimensions of flooring. When using a heater during winter months,humidity may be much lower than the acceptable range. During the warmer months,maintain humidity levels using an air conditioner, dehumidifier, or by turning on your heating system periodically.

NEW CONSTRUCTION OR REMODEL

All work involving water, such as pouring basement concrete floors, drywall and plasterwork, plumbing, etc. must be completed well in advance of the floor delivery. Ensure that the building is enclosed.Where building codes allow, permanent heating and or air conditioning systems should be operating at least two weeks preceding installation and should be maintained during and after installation.If it is not possible for the permanent heating and/or air conditioning system to be operating before,during and after installation,a temporary heating and/or dehumidification

system that simulates normal living(occupied)conditions can enable the installation to proceed until the permanent heating and/or air conditioning system is fully operational.Your job site should have a consistent temperature between 50°F & 100°F(10°C & 38°C) and relative humidity(RH) of 35%-85% which should be maintained continuously thereafter.

RECOMMENDED INSTALLATION AREA

Do not install vinyl planks over carpet or any foam underlayment.This product is not suitable for any outside use,sun rooms/solarium,saunas,seasonal porches,camping trailers,boats,RV’s or rooms that have a potential of flooding.Do not install in rooms or homes that are not temperature controlled. Exposure to long term direct sunlight can cause damage to your floor. Failure to properly shade or UV tint windows can discolor, fade,or buckle vinyl planks. Use window treatments or UV tinting on windows.Vinyl planks are not intended for use on stairs or vertical surfaces. Do not glue, nail, screw or fasten to substrate. Install cabinetry, island and peninsula counters, vanities, tubs,and showers first. Then install vinyl planks around them.]

BASEMENTS AND CRAWL SPACES

Concrete slab or ground must be dry. Ensure that crawl spaces have open vents year round to ensure proper air circulation and prevent moisture build up.The ground in the crawl spaces must be completely covered using 6 mil black polyethylene.Crawl space clearance between the earth and underside of joists should be no less than 18 in.and the perimeter vent area should be equal to 1.5% of the total square footage of the crawl space or as mandated by code.

RADIANT HEATED SUBFLOOR

This product can be installed over radiant heat concrete sub floors.The radiant heating system must be cast 1/2 in.below the surface of the concrete slab and should be operating at least 2 weeks before installation. Set the temperature of the radiant

heating system to 68°F 48 hours before,during and 72 hours after installation.You may gradually raise the temperature starting 72 hours after installation.The finished floor surface must not exceed 85°F(29°C)for the life of the floor. Because radiant

heat creates a dry heat that can lower interior humidity levels, it may be necessary to add a humidifier to maintain the humidity level between 30-85% to prevent damage to the vinyl floor. Consult with the radiant heat system manufacturer to ensure that the system is compatible with vinyl flooring.

MOISTURE BARRIER/UNDERLAYMENT PADDING

CONCRETE SUBFLOOR

When installing over a crawl space or concrete slab,it may be necessary to use a moisture barrier to prevent moisture migration.A plastic film with a minimum thickness of 6 mil should be placed with a 4-6 in.(101.6-152mm)overlapped seam,and taped with a suitable tape. This should be combined with an approved underlayment padding for floating floors.

EXPANSION GAP

A required gap width of 1/4 in. is required around the perimeter of the floor and between the floor and all vertical obstructions.

Do not place permanently mounted structures such as kitchen counters/cabinets on the installed floor.

TRANSITION MOLDING

For floating installation,transition T-molding is required in the following cases:floors spanning greater than 30 ft.in width and 50 ft. in length;doorways and archways less than 4 ft.wide.

TOOLS AND MATERIALS BASICS

Tape measure · Moisture meter(wood concrete or both) · Utility knife & straight edge· Measuring tape · Shears for cutting around irregular shaped objects(pipes)·6mm(1/4 in.)spacers ·Pencil ·Tapping block · Soft faced hammer · Eye protection · Broom

Helpful Pointers

GENERAL TIPS

Make sure your work area is well it. Good visibility ensures that color is consistent and that visually defective planks are detected and removed.

The minimum length of the first and last plank is 8 in. If the last plank will be less than 8 in., adjust the length of the first plank. The remainder of the last plank can be used as a starter board on the following rows.

Using a shorter piece at undercut door jams will help when fitting flooring in place.

Never hit the flooring directly with the tapping block and be careful not to fracture floor edges,

Preparing for Installation

First, determine how you want the flooring to run. Typically for plank products, the flooring runs the length of the room. There may be exceptions since it is a matter of preference. To avoid narrow plank widths or short plank lengths near the walls/doors, it is important to do some pre-planning. Using the width of the room, calculate how many full boards will fit into the area and how much space remains that will need to be covered by partial planks.

Lay the first row of planks along a chalk line and trim to fit the wall allowing ¼ inch expansion space. If you start the first row with a full width plank, it will be necessary to trim the tongues next to the wall and then place the cut edge next to the wall. Use a utility knife and a straight edge to score the top surface of the plank and then bend it downward to separate. If the starting wall is out of square, it will be necessary to scribe the first row to match the wall, allowing the opposite side of the row to present a true square base for the rest of the floor.

Use expansion gap spacers to keep the floor about ¼ inch away from the walls.

Remove wall base and undercut door jambs. Do not secure individual planks to the sub floor as it is designed to be a floating floor. Do not install cabinets on top of floor.

Step 1 Making a taping block

Cut a piece of flooring down to about 3 inches by 4 inches leaving the tongue on one side. The side opposite the tongue should be flat as you will be taping this side with hammer.

Step 2 The First Row

Start by matching the tongue of the short side of a plank with the groove of the short side of another plank. Lock the short end of the plank by inserting the tongue into the groove at an angle and drop it in place. Continue joining the short sides until you have a row of planks for the length of the room.

Step 3 First Piece of the Second Row

You can often use the leftover piece from the end of first row to begin the second row. This piece must be at least 10” long. Visually, the installation will look more natural if the starting planks are a variety of lengths. After installing the first row of planks, line up the first plank of the second row, so the outside end is even with the outside end of the plank in the first row. Lock the long side of the second-row plank onto the plank on the first row by inserting the tongue of the second plank into the groove on the first plank while holding the plank at a 20-degree angle from the floor. Press the second plank down flat and the tongue will lock firmly into place.

Step 4 Second and Subsequent Planks in the Second Row

Working firstly with the short sides, align the tongue of the second plank with the groove of the first plank while keeping the long side about a quarter inch away from the first row. Then angle these two pieces up by about 20 degrees. Use a taping block to tap the second plank into position four times. First, where the two planks meet, second across from the joint in the previous row and third at the left side of the plank and last on the short side of the new plank.

Step 5 Subsequent Rows

Ensure each plank of each subsequent row has at least 10 inches of overlap; that they are fitted brickwork style. This ensures a strong fit.

Step 6 Fitting the Last Row and Doorways

Spectrum rigid core can also be installed with a pull bar or tapping block and rubber mallet or hammer in difficult areas, such as the last row, and when fitting around door trim. Use a pull bar and rubber mallet or hammer to lock the joints together in the last row. Always use a pull bar on the cut edge of the plank. Factory edges can be damaged if the pull bar is used directly against the tongue or groove.

Repairs

In the unlikely event that a plank is damaged for whatever reason, the simplest method is to disconnect the planks carefully (protecting the tongue and groove edges) until the damaged plank can be removed. Then replace the damaged plank with a new one and re-assemble the disconnected planks. This typically works for planks that are close to the two long perimeters of a room. For damaged planks that are not close to the perimeter, you may have to remove the damaged planks and insert new pieces without the short and long end grooves.

1.Using a sharp utility knife and a straight edge, cut out the center of the damaged plank by leaving approximately 1-inch strip attached to the adjacent planks.

2.Carefully cut back from the four corners of the plank to the inside edges. Carefully remove the plank edges from the adjacent planks making sure the tongues and grooves of the adjacent planks are not damaged.

3.Using a sharp utility knife, remove the tongue strip on both the long and short ends of the replacement plank. In addition, remove the groove strip of the short end of the replacement plank.

4.Place two-sided carpet tape with one half under the sides of the adjacent planks where the tongues and the groove of the replacement plank have been removed. Only the top side release paper of the carpet tape should be removed. Leave the bottom side of the release paper in place - NOT taped to the sub floor.

5.Position the replacement plank by engaging the groove of the long side into the tongue of the adjoining plank and pushing down on the other three sides. The carpet tape will hold the replacement plank in place with its adjacent planks. Use a hand roller to further secure the tape.

NOTE: Rooms larger than 1500 sq. (50 ft.x30 ft.) require the use of coordinating T-molding transitions. Doorways and archways less than 4 ft. wide also require the use of T-molding transitions.

NOTE: Save any leftover planks. Do not discard as they are color matched (dye-lot) to your floor. They can be used for replacement in the event you need to replace a plank in the future.

Accessories

T-Molding: Used to create a transition between floor coverings of similar heights or to cover an expansion gap.

Stair Nose: used in conjunction with flooring installed on stair steps or finished edges of a higher-level floor like in a Sunken Living room.

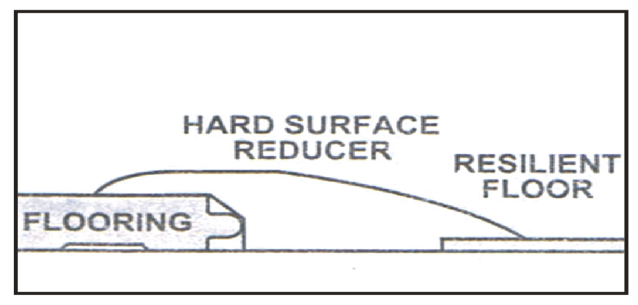

Hard Surface Reducer: Used to transition to another hard surface flooring of different heights such as tile, vinyl, or concrete.

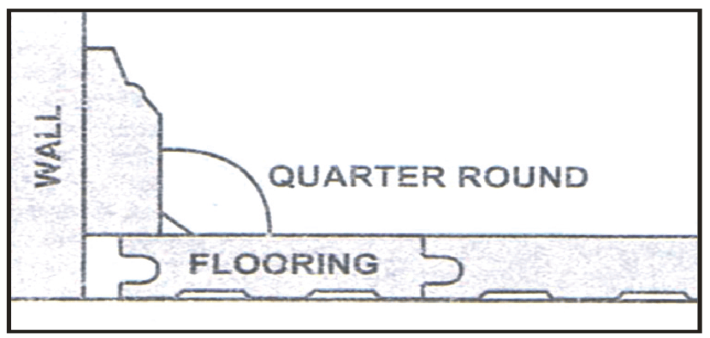

Quarter Round: Used to cover the expansion space between the wall base and your flooring, it can also be used to make smooth transitions between the floor and cabinetry. it can be used with or without wall base molding.

Care and Maintenance

DAILY MAINTENANCE

Sweep, dust, damp mop, or vacuum your floor regularly to remove any particles that could cause abrasion or scratch your floor.

CAUTION:

Vacuums with a beater bar or power rotary brush head can damage a and damage a floor and should never be used.

Use a damp mop to remove spots and soil. Use any high-quality, p/h-neutral vinyl cleaner. Alternatively, use a non-rinsing, biodegradable cleaner that leaves no residue or haze.

For lightly soiled area, clean with distilled water.

HINT: For best results, clean the floor in the same direction of the planks, When the cleaning cloth/mop becomes soiled, rinse or replace it with a clean one, following up with a clean, dry cloth will remove residual streak marks and spots.

Avoid spills of acidic products (juice, soft drinks, wine, etc.) on the floor. Clean spots immediately.

Do NOT use a steam cleaner.

Do NOT use any cleaning agents containing wax, oil or polish. Left over residue will form a dull film.

Do NOT use steel wool or scouring powder which will scratch the floor.

Do NOT use any dust cleaners, as they may cause your floor to become slick or damage the finish.

Avoid spills of paints, dyes, or harsh chemicals.

Avoid long term exposure to direct sunlight. Use window treatments or UV tinting on windows.

BRANDED OR OFF-THE-SHELF FLOOR CARE PRODUCTS

If none of the above are effective and you choose to use a store-bought product, test the product in a non-conspicuous area (i.e., closet, corner, or scrap pieces) for potential adverse side effects.

PREVENTATIVE MAINTENANCE

Protect your floor when using a dolly for moving furniture or appliances. Protective sheets and/or plywood may be needed. Never slide or roll heavy furniture or appliances across the floor.

Use fiat floor protectors (nylon or felt) on all furniture legs. Clean protectors periodically to remove grit that may become embedded and cause scratching.

Avoid excessive exposure to water from being tracked in during periods of inclement weather.

Minimize abrasive material and dirt by placing mats on both sides of exterior doors and by using area rugs in high-traffic areas.

Rearrange furniture and rugs periodically to avoid uneven color and shade changes from light exposure.

Use protective mats beneath rolling chairs and keep furniture casters clean.

Use NON-RUBBER backed mats at ail entrances to avoid discoloration from asphalt driveways or prevent dirt and grit from being tracked onto your floor. Rubber backed mats can discolor your floor.

We recommend the use of a hard surface (non-studded), non-rubber mat to protect your floor from office chairs with casters. Light, rolling furniture should be outfitted with broad-surface, non-staining casters that have been engineered for hard surface floors. Such casters should be a minimum of l in. (2.5 cm) wide and at least 2 in. (5.1 cm) in diameter.

Keep pets' nails trimmed.

Remove shoes with cleats, spikes or exceptionally pointy heels before walking on the floor.

CLIMATE MAINTENANCE

Care should be taken to control humidity levels within the 35% - 85% range.

Dry Climates: A humidifier is recommended to maintain humidity levels. Wood stoves and electric heat tend to create very dry conditions during the winter months this also will cause shrinkage in flooring.

Humid, Wet Climates: By using an air conditioner, heater, or dehumidifier proper humidity; levels can be maintained to prevent excessive expansion due to high moisture content.

Note: This instruction is especailly for SPC floor installtion.

.png?v=20250402)

Richard Liu

Richard Liu +86.519.8585.1798 Fax:+86.519.8585.6878

+86.519.8585.1798 Fax:+86.519.8585.6878 info@xinflooring.com ( 7*24 hours online)

info@xinflooring.com ( 7*24 hours online) Science & Technology, Industrial Park, Hutang Town, Wujin District, Changzhou City, Jiangsu Province, 213162, China.

Science & Technology, Industrial Park, Hutang Town, Wujin District, Changzhou City, Jiangsu Province, 213162, China.