News & Events

The Advantages of the Bending-Floor Flush Stair Nosing and its Difference from Traditional Covered Stair Board.

The wrapping production process of SPC/WPC Bending-Floor Flush Stair Nosing is different from that of the traditional one , but a new product developed by our company, which has been recognized and favored by many of our customers since it came out.

SPC or WPC base material are used for the traditional wrapping production, with the gluing of the prepared color film and wear layer, which has the advantages of high efficiency and short delivery time, while the disadvantages are also quite obvious, since it skips the process of UV, the wood surface, thickness(Height difference problem), EIR surface, click system also will not be completely consistent with the floor. Different from the base material of SPC and WPC Floor, this material is produced by a different process as well. Normal stair nose also requires notching for the second time, and even then, it cannotget the same click and locking force as the floor, the size of the normal stair nose and stair tread are fixed, which cannot meet the personalized requirements of the customer for different nose size. Stepping surface width size of the board is also unified and fixed, can not meet the increasingly innovative personality of the designer requirements, for instance,the stair board with more than 300mm stepping surface is almost difficult to finish through the normal wrapping process.

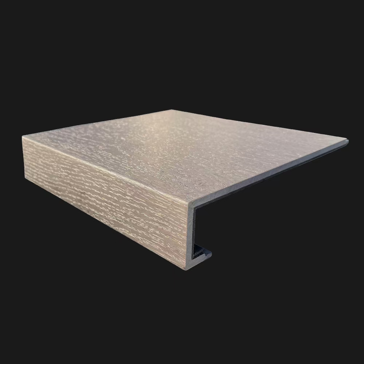

But the Bending-Floor Flush Stair Nosing promoted by our company can fundamentally solve the shortcomings in the traditional wrapping technology under the use of real floor products or full core material, through customized professional equipment and data settings, the floor products or full core material are folded into the customers’size after heating and bending.

The advantage is obvious:

1- Can be perfectly connected with the floor, no height difference, no gloss difference;

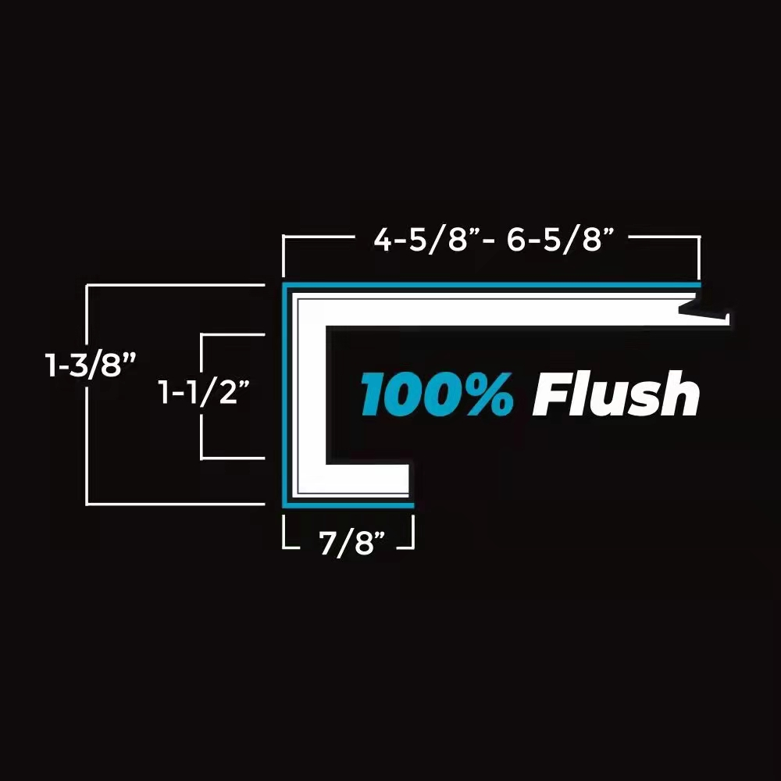

2- Dimensions (stairnose/stair tread width, nose size, etc.) can be flexibly customized to meet customer's personalized design requirements;

3- Can achieve the same embossed in registered surface design requirements as the floor;

4- Click system is exactly the same as the floor, with enough locking force, easier to install and ensure the joint effect;

5- Can achieve all kinds of grain requirements consistent with the floor;

6- It is easy to meet the personalized requirements of EVA or IXPE on the back of the stairnose or stair tread, with comfortable feeling of feet and quiet noise reduction;

Above each point of the stair nose/stair tread's unique advantages, the only shortcoming is the production efficiency is slow and the delivery date is longer. But we will improve the production process with continue to research and develop, we firmly believe that in the near future we can achieve more efficient production process to meet customers' requirements of bulk ordering and fast delivery.

.png?v=20250404)

Richard Liu

Richard Liu +86.519.8585.1798 Fax:+86.519.8585.6878

+86.519.8585.1798 Fax:+86.519.8585.6878 info@xinflooring.com ( 7*24 hours online)

info@xinflooring.com ( 7*24 hours online) Science & Technology, Industrial Park, Hutang Town, Wujin District, Changzhou City, Jiangsu Province, 213162, China.

Science & Technology, Industrial Park, Hutang Town, Wujin District, Changzhou City, Jiangsu Province, 213162, China.