News & Events

Waterproof Click Installation&Maintence for WPC floor

Comprehensive Installation and Maintenance Instructions

It is important to work out of several cartons to mix the patterns when installing this flooring product to enhance the beauty of nature without having duplicate planks beside each other. Several colors in Xinfulai WPC feature a wide range of color variation, therefore it is important to plan the installation of the products as to mix those colors together to create the desired visual. Xinfulai WPC offers the natural colors and texture variations that are abundantly available in nature to give a beautiful finished installation within the home. Xinfulai WPC should never be installed outdoors, or in areas that will not constantly stay between 23° F and 85° F.

BEFORE YOU BEGIN INSTALLATION , it is extremely important that subfloor preparations are performed as follows:

SUBFLOOR:

1. Subfloor must be level, flat, and structurally sound. The subfloor levelness must not exceed 1/8” level within a 6' span in all directions. It is suggested to use either a level or a straightedge. Grind high spots down and level low spots with a water resistant non-shrinking Portland leveling compound. Be certain the floor joists do not impede the floor flatness as required. Unevenness can cause problems with the integrity of the locking system and cause the system to disengage.

2. Concrete substrates must be fully cured before installation for a minimum of 30 days or more. Concrete subfloors must be dry, smooth, and free from dust, solvent, wax, asphalt sealing compounds, and other materials that may compromise the backing of the flooring.

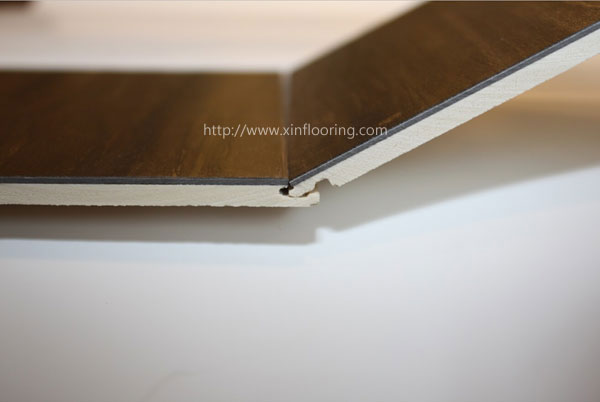

3. Underlayment with cushioning properties may not be used under Xinflooring WPC under any circumstances, as the product has an attached IXPE pad.

4. It is the installer's responsibility to be certain the subfloor guidelines are followed before installation begins.

Xinflooring WPC may be installed above, on, or below grade over ACCEPTABLE SUBFLOOR TYPES:

1. Concrete slab

2. APA Rated plywood underlayment

3. Properly prepared gypsum cement.

4. Underlayment grade particleboard

5. OSB minimum ¾”

6. Existing Hardwood floor

7. Ceramic Tile

8. Single layer resilient tile and sheet vinyl

9. Floating or fiber back cushion vinyl products are not recommended

10. Existing hard surface floor covering must be securely fastened

WARNING: Existing resilient floor coverings and black asphalt adhesive may contain asbestos. Improper removal procedures could release asbestos fibers into the air. Asbestos fibers, when inhaled, could cause serious bodily harm. Do not sand or dry scrape these materials. If removal of existing floor coverings is necessary, be certain that all precautions are taken and proper procedures are followed.

GENERAL GUIDELINES:

ACCLIMATION: HVAC system for the installation must be operational and turned on to provide a temperature of 60-80°F. The product should be brought to the same temperature before installation.

DIRECT SUNLIGHT: The installed flooring should be protected from excessive exposure to direct sunlight.

CRAWL SPACE: The bottom of wooden subfloor joists must be a minimum of 18” above ground surface.Minimum 6 mil black poly sheeting must be in place covering 100% of the ground and overlapped a minimum of 6” at seams acting as a moisture barrier. The poly sheeting must run up the walls no less than 6”. Air vents must be open on all sides with no less than 1.5% air vent opening compared to the total crawlspace area.

RADIANT HEAT: Only embedded radiant heat is recommended. Temperature should be reduced three days before installation to no more than 65°F. After installation, slowly increase the temperature a maximum of 5°F per 24 hour period. Temperatures should never exceed 85°F. Warning: Heating mats are not recommended for our WPC flooring.

EXPANSION GAPS: A minimum of 1/4” expansion gap must be allowed for all vertical obstructions including door jambs. If lengths or widths of installed areas of the product exceed 60 feet in any direction, a minimum of 3/8 ” expansion gap must be allowed for all vertical obstructions, including door jambs.

INSTALLATION TOOLS

1. Tape measure

2. Tapping block (trimmed piece of flooring)

3. Pencil

4. Pry bar or pull bar

5. Chalk line

6. Crosscut power saw

7. 3M Scotch-Blue Tape 2080

8. Rubber mallet

9. White wood glue

IMPORTANT REQUIREMENTS BEFORE INSTALLING:

Be certain a minimum of 1/4 ”expansion gap is allowed for all vertical obstructions including door jambs. If lengths or widths of installed areas of the product exceed 60 feet in any direction, a minimum of 3/8” expansion gap must be allowed for all vertical obstructions, including door jambs. Please check local building codes before undercutting metal door jambs.

Be certain the subfloor is sound, flat, dry, and level. Floor levelness should not exceed 1/8 ” in a 6' radius span. Using a 6' or longer level or straightedge, slide along the subfloor looking for low and high areas, which must be either ground down or filled with an approved Portland based leveling compound. Xinfulai is not responsible for flooring failures resulting from unsatisfactory subfloors.

Wood subfloors must be secure making sure it is either nailed or screwed every 6 ” along the joists to avoid squeaking.

Xinfulai recommends crawl spaces have a black 6 to 20 mil thick moisture barrier properly installed. Moisture will not affect Xinfilai WPC but it may permeate into the walls and structure of the building exposing you to problems with mold (and/or) mildew (and/or) excessive subfloor expansion/contraction.

Do Not install Xinfulai WPC where it will be in direct sunlight for extended periods of time.

Xinfulai cannot be responsible for installing planks with visible defects.

Existing floors such as ceramic, resilient tile and non-cushioned sheet vinyl must be well bonded to the subfloor. Do not sand existing vinyl floors, as they may contain asbestos.

.png?v=20250420)

Richard Liu

Richard Liu +86.519.8585.1798 Fax:+86.519.8585.6878

+86.519.8585.1798 Fax:+86.519.8585.6878 info@xinflooring.com ( 7*24 hours online)

info@xinflooring.com ( 7*24 hours online) Science & Technology, Industrial Park, Hutang Town, Wujin District, Changzhou City, Jiangsu Province, 213162, China.

Science & Technology, Industrial Park, Hutang Town, Wujin District, Changzhou City, Jiangsu Province, 213162, China.